|

Buzzers: These Buzzers buzz when ever there is load parting. The yellow

colored indicator (LSPAR) comes on. Right next to this indicator is a 110 Volts outlet socket.

At the moment it is covered with a cap that is chained to the socket itself. The green colored

switch (BIS) is the resetting switch used to silence the buzzers once things are set right. |

|

That's the color code of the brake pipes, to prevent any interchange or wrong connections.

It's painted on the inside wall over the wind shield of the cab. |

|

Cab heater and Fire extinguisher |

|

A view of the RHS corner of the loco control desk:

- "A" Horn valves: The horn is pneumatic and these are the valves that have

to be pressed to blow horns. Two valves - one for the front and the other for the rear.

- "B" Emergency brake flap: A flick of the lever that holds the flap down

and the flap is off its seat. Brake pipe pressure is lost and the train screeches to a halt.

- "C" flasher light control unit: More details of it latter on in another

picture.

- "D" Marker lamps control unit: There are marker lamps at both the ends of

the loco and these are either yellow or red depending on the direction the loco is

traveling. Obviously the marker at the front is yellow and the one at the rear red.

|

|

A view of the central portion of the control desk:

- NR2 is the notch indicator.

- ZPT2 is the switch used to lower, raise and select the panto to be

raised.

- ZLC1 and ZLC2 are switches used to switch on and off

the lights in the cab.

- BPISX is the red colored switch used to flash the green colored

lamps located on the outside wall of the cab on the side top corners. The WAP 4 is a

high speed loco and many a times these lamps are used to exchange the " All Right"

signal with the ASM and other ground staff.

|

|

The switch board and the indicator lamps module located in the driving cab. |

|

Ammeters & Voltmeters:

- AM4 TM4: This ammeter indicates the current flowing through Traction

motor no. 4. A WAP 4 loco may draw a max current of 1000 Amps for a max duration of 10

minutes. Current of 900 Amps may be drawn continuously.

- U-5 TM-5: This volt meter indicates the voltage across Traction motor

no. five. The voltage at no time should exceed 750 voltage. When a quick acceleration

is required and if the voltage exceeds 750 volts due to rapid increase of notches, the

shunting notch (weak field lever or the "MPS") may be put into position one after notch

20. This will lead to an increase in the amps across the traction motors but a reduction

in the voltage across it. The notches may than be increased and again if the voltage

goes up the shunting notch may be put at position two.

- U-6 TM-6: This voltmeter indicates voltage across Traction motor six.

Old timers may wonder as to why there are two voltmeters and only one ammeter, because

there used to be two ammeters and one volt meter in all loco upto now. The reason is

that now, higher than permissible voltage across the TM's for burnt out of TM's.

|

|

- The round steering like thing is used to increase the notches.

- The MPJ lever is used to change the running direction of the loco viz reverse or forward.

- The MPS lever is the shunting notch or the weak field lever. This is

brought into operation to prevent voltage across traction motors from increasing beyond

750V. This enables rapid acceleration as more notches can be open as the voltage drops and

also the TMs speed up due to weakening of the field.

|

|

These days trains are run at Max speeds. Drivers are instructed to drive in "air brake style"

This involves rapid acceleration and equally rapid & frequent breaking. To ensure that the

loco can accelerate immediately after brake application, brake release must be immediate. Or

time is lost as the driver waits for brakes to release(Impatient drivers have been known to

end up with fractured couplers). The Green colored switch shown here, when pressed results in

immediate brake release. The Buzzer and LED shown here come on in case of load parting. The

other green colored switch is to reset the buzzer after the "All Right" signal is given. |

|

A view of the LHS corner of the cab:

- "A": A9 , train brakes

- "B": SA 9, Loco brakes

- "C" Speedometer. Now a days we have modified speedometers that record

speed on floppy instead of graph paper.

- "D": Air flow meter. This indicates the flow of brake air

- "E": Ash tray. I have come across it the first time. Has IR started

encouraging smoking among staff and crew ?

- "F":Valves / switches to blow horn

- "G": Gauges to indicate brake air pressure.

|

|

Cut out valves: These valves are situated in the lower LHS corner of the

loco. One can cut out air to the various pneumatic equipment in the loco. There are two valves

for SA9, two valves for SA9 , one for the wiper and two for the horns. |

|

These are the capacitors for the Arno and compressor. These are located in a cabinet on the

back wall of the cab. |

|

A close view of the brake air pressure gauges situated in the extreme LHS corner of the cab.

The gauge with the two coiled pipes connected to it shows the main reservoirs pressure and the

feed pipe pressure. The larger gauge with graduations from 0 to 10 shows the air pressure in

the brake pipe. |

|

ZLE3 is the switch for the light in the compartment on the back wall of the

cab that houses the capacitors for the Arno and compressor.

There are two flashers outside the

cabs. One on each cab. There are two control units, one in each cab for controlling the

flashers. Normally one unit controls one flasher If any one of these flasher units fails than

the other unit can control the flashers irrespective of their location.

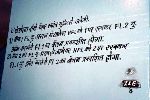

The writing on the wall reads: If the switch is on "0" position both flashers

will run individually on independent units. If the flasher unit in cab one malfunctions than

the HFL should be put on position "1" Now if the flasher unit in cab two is switched on it will

run the flasher located on cab one. If the flasher unit located in cab two malfunctions than

HFL should be put on position "2" and flasher unit located in cab one will run the flasher unit

located on top of cab two. |

|

When ever a loco crosses a dead zone the "DJ" has to be opened as a result of this all

electrical in the loco including the head light gets switched off. To avoid this a DC-DC

Converter is being retrofitted in locomotives. These converters step down the 110 volts from

the batteries in the loco to 32 volts which is than supplied to the head light when ever the

loco is passing a dead zone. What is shown in this pic is merely the control unit for this

converter, there are other transformers which actually do the converting and they can be seen

in another pic. |

|

This is the VB box. This is a safety device (interlock box) to ensure that OH supply is

switched off before a human enters the interior of the loco. The large socket takes in the

ZPT key. The keys numbered one to four are the fitchet keys. |

|

The battery charger. |

|

This is the GR handle. The notches can be manually increased from here. |

|

The transformer that steps down 110 volts from the batteries to 32 volts. This is supplied to

the head lamps when ever the loco crosses a dead zone. |

|

This is the contactor for the GR. One can see the thin wire like things behind. These are

resistors that come into play when the notches are increased. |

|

Smoothening reactors: The loco takes in AC from the OHE. This has to be

converted to DC before being fed to the traction motors. The main rectifier does this job.

But the out put of the rectifier is not pure DC when connected to a CRO it does not give a

100% smooth straight line. To rectify this the smoothening rectifiers are employed. They

smoothen the out put of the rectifiers rendering pure DC out put. |

|

The Pump that circulates the oil in the main transformer to keep temperature under control. |

|

Resistance contactors and line contactors. |

|

"A": That's the loco reversing contactor. |

|

"A": That's the DJ main contactor. It's something like a "AB" switch. When in open position it isolates the loco from OHE. The DJ has to be opened whenever the loco crosses a dead zone. |

|

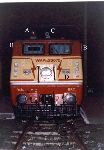

Front view of the loco:

- "A": Flasher lamp.

- "B": Green colored indicator lamps used to exchange signals with ground

crew.

- "C": Horn.

|

|

Lower front view of the loco:

- "A": A metal strip about three inches wide to protect the FP and BP valves

when there is a cattle hit.

- "B": Cow catcher.

- "C": Auxiliary air reservoir.

- "D": Marker Lamp.

|

|

- "A": "Skid" A metallic wedge to prevent the loco from rolling away

when parked.

- "B": The Bogie. WAP 4 has a cast iron bogie.

|

|

A view of the DJ main contactor from the other side. |

|

A front full view of the Majestic WAP 4 from Vadodara at Badnera. This loco had come to

Bhusaval for It's POH. When ever locos under go POH they have a first trial run. They are made

to haul lightly loaded passenger train. A WAM 4 is right behind this loco just waiting to

take over in case the newly overhauled loco acts up. "A": This is the green

colored signaling lamp. This is used to exchange signals with ground crew when the loco runs

at high speeds.

|