Electric Locomotive Classes – DC, Dual Current, Battery & Dual Traction

On this pageInformation on AC traction locomotives can be found this page.

DC Locomotives

The first mainline electric locomotive in India. Made by Vulcan Foundry starting in 1928, with electricals from Metropolitan Vickers, these were initially class EA/1 of the GIPR. Rated at 2160hp, they had a 1-Co-2 wheel arrangement. 22 were supplied for GIPR's operations in the Mumbai region. They were eventually replaced in the 1960s by the various WCM class locos. EA/1 #4006 is preserved at the National Railway Museum as WCP-1 #20005.

These were test locomotives ordered by the GIPR from various manufacturers around the same time as the WCP-1 (EA/1) to gauge performance and decide which of them would be suitable for serial production runs. Only one of each type was ever made.

The WCP-2 (EA/2) was made by SLM/MetroVick with the same wheel arrangement as the WCP-1. This loco (#20024) is now preserved at the Nehru Science Centre, Mumbai.

The WCP-3 (EA/3) was made by Hawthorne Leslie/Marconi Company and had a 2-Co-2 wheel arrangement.

The WCP-4 (EA/4) was made by Hawthorne Leslie/Brown Boveri and also had a 2-Co-2 wheel arrangement.

Made by English Electric/Vulcan Foundry (with auxiliaries from Westinghouse) in 1954, these were the first electrics on IR with the now familiar Co-Co wheel arrangement. 7 were ordered to replace the aging WCP class of electrics running on CR. Air brakes for loco, and regenerative braking. Vacuum train brakes. Three different series-parallel motor combinations are available, as well as weak field operation. MU operation not possible.

They were also the longest serving non-steam locos on IR, with a couple of units running well into the 1990s, still hauling prestigous trains like the Deccan Queen and Indrayani Expresses. They were rarely used for freight. They were characterized by their large size and unusually long hoods. The position of the entrance doors is also unusual, being not at the sides of the cabin, but through an entrance in the middle of the loco body side. Several of these were rebuilt in 1968 with better traction motor and suspension components. They were withdrawn at the beginning of 2000, with one #20068 being preserved at the Regional Rail Museum in Chennai where it is the main exhibit.

| Builders | English Electric/Vulcan Foundry |

| Traction Motors | 6 axle-hung, nose-suspended, force-ventilated English Electric 514/2C DC motors (615hp, 700V, 700A, 738 rpm); weight 3594kg |

| Gear Ratio | 59:16 |

| Pantographs | Two English Electric, PNL4-F1 |

| Horsepower | 3700hp |

| Axle Load | 20.83t |

| Bogies | Co-Co fabricated swing bolster with equalizer beams |

| Weight | 123.9t |

| Starting TE | 31 tons at 25% adhesion |

| Continuous TE | 21 tons |

| Max. Speed | 120km/h |

| Length Over Buffers | 20834mm |

Slightly smaller than their WCM-1 cousins, these English Electric/Vulcan Foundry locos were initially built to run on the 3kV DC lines around the Calcutta area. 12 were in service in the area from 1956 to 1960, when the area was converted to 25kV AC, rendering them useless. RDSO then modified these locos to run on the 1.5kV DC lines around Bombay without any loss of power. Three series-parallel combinations possible, and weak field operation. Air brakes for loco, vacuum brakes for train. Max axle load of 18.8t. Auxiliaries by Westinghouse (compressor, etc.) and North-Boyce (exhauster). Unlike the WCM-1, these had normally positioned doors next to the cabs. They were in service until 2000, mostly hauling passenger shuttles between Pune and Karjat in their later years.

| Builders | English Electric/Vulcan Foundry |

| Traction Motors | English Electric 531A (520hp, 1450V, 260A, 1165 rpm, weight 3445kg); Six motors, axle-hung, nose-suspended, force-ventilated |

| Gear Ratio | 62:16 |

| Pantographs | Two English Electric PNL6-B1 |

| Horsepower | 3100hp |

| Axle Load | 18.8t |

| Bogies | Co-Co fabricated; swing bolster with equalizer beams |

| Weight | 112.8t |

| Starting TE | 31 tons at 25% adhesion |

| Continuous TE | 14 tons |

| Max. Speed | 120km/h |

| Length Over Buffers | 20066mm |

Built by Hitachi in 1957-1958, these were the smallest of the WCM series. Like the WCM-2, they were also initially used on the 3kV DC network around Calcutta, but were converted to 1.5kV and transferred to the Bombay area. Only three were ever made, nos. 20073-5. Auxiliaries by Westinghouse and North Boyce. The WCM-3 units were characterized, apart from their dimunitive size, by separate light enclosures for the parking/ marker lights (next to the headlight) and the tail lamps (just above the buffers). In their later years, they were mainly used for freight. They were withdrawn in the 1980s; none of them have been preserved.

| Builders | Hitachi |

| Traction Motors | Hitachi HS 373-AR-16 (600hp, 1450V, 330A, 927 rpm); axle-hung, nose-suspended, force-ventilated |

| Gear Ratio | 51:16 |

| Horsepower | 3600hp |

| Axle Load | 19.1t |

| Bogies | Co-Co cast steel |

| Weight | 113t |

| Starting TE | 28.2 tons at 25% adhesion |

| Continuous TE | 16.9 tons |

| Max. Speed | 120km/h |

| Length Over Buffers | 19583mm |

Built in 1960 by Hitachi as the bigger, heavier and more powerful version of the WCM-3. 7 of these were made and put to service hauling expresses and other prestigious trains, but were relegated to freight operations due to technical issues. These are the only WCM series locos to be used almost exclusively for freight duties (despite the M=mixed classification). Auxiliaries by Westinghouse and North Boyce. Unlike the WCM-3, they have normal light enclosures. Three series-parallel motor combinations, and weak field operation. Air brakes and regenerative braking for loco, vacuum brakes for train. These are also the last imported engines to come with bonnets (noses) at either end.

| Builders | Hitachi |

| Traction Motors | Hitachi HS 373-BR (675hp, 700V, 765A, 850 rpm, weight 4500kg); axle-hung, nose-suspended, force-ventilated |

| Gear Ratio | 73:16 |

| Pantographs | Two, type KP-120 |

| Horsepower | 4000hp |

| Axle Load | 20.8t |

| Bogies | Co-Co fabricated |

| Weight | 125t |

| Starting TE | 31.2 tons at 25% adhesion |

| Continuous TE | 25.3 tons |

| Max. Speed | 120km/h |

| Length Over Buffers | 20000mm |

Built in two batches between 1960 and 1962 by CLW to RDSO specifications, these are the first indigenously manufactured DC electrics. The first one #20083 was named 'Lokmanya'. Auxiliaries by Westinghouse and North Boyce. They have almost the same component and equipment list as the WCM-4.The same Hitachi HS 373-BR traction motors, but less heavier wiring and changed gear ratio, outputting 3700hp. Three series-parallel motor combinations, and weak field operation. Air brakes and regenerative braking for loco, vacuum brakes for train. Although they saw occasional freight use, they were almost always seen hauling express and passenger trains. They were all painted to match the livery of the famed Deccan Queen Express.

In the WCM series, these were the first to use half-collector pantographs. There was a wide variation in the side window grille profiles, and very few of these units looked alike. Several were also fitted with CBC couplers. There were a few in use until late 1999, mostly for departmental needs and short passengers, but were completely withdrawn by the middle of 2000. All were scrapped, save one, #20103, which is preserved at CLW.

| Builders | CLW |

| Traction Motors | Hitachi HS 373-BR (675hp, 700V, 765A, 850 rpm, weight 4500kg) |

| Gear Ratio | 59:16 |

| Pantographs | Two Faiveley AM28 BB |

| Horsepower | 3700hp |

| Axle Load | 20.3t |

| Bogies | Co-Co fabricated |

| Weight | 124t |

| Starting TE | 31 tons at 25% adhesion |

| Continuous TE | 21.7 tons |

| Max. Speed | 100km/h |

| Length Over Buffers | 20168mm |

These were the last pure DC locomotives to be made by CLW. Only two were produced (#20187 and #20188) in 1996 and sent to Kalyan shed. Hitachi HS1520A traction motors with better windings to provide 4600hp. AC auxiliaries, underslung compressor, Siemens static converter, Elgi compressor, high-adhesion bogies similar to the WAG-7. These were almost exclusively used for light freight duties, perhaps because CR found the WCAM-3 to be a more versatile loco. #20187 was destroyed in a fire, but was restored by Kalyan shed later. Their duties almost never took them beyond Lonavla on the Pune line. Though in the early 2000s, they were assigned to haul passengers on the Diva - Panvel route.

In 2012, with the impending conversion of the Mumbai region to 25kV AC, they were sent to the Bhusaval Workshops and converted to pure AC working with many shared electricals from the WAG-7. As of Feburary 2022, they still soldier on in inferior duties (lighter loads, max speed of 70km/h) after having failed high speed oscillation trials post conversion to AC.

| Builders | CLW |

| Traction Motors | Hitachi HS-1520A |

| Gear Ratio | 18:64 |

| Pantographs | Two Faiveley AM18B |

| Horsepower | 4600hp |

| Axle Load | 20t |

| Bogies | High-adhesion Co-Co |

| Weight | 120t |

| Starting TE | 39.6 tons at 27% adhesion |

| Continuous TE | 36 tons |

| Max. Speed | 105km/h |

| Length Over Buffers | 20394mm |

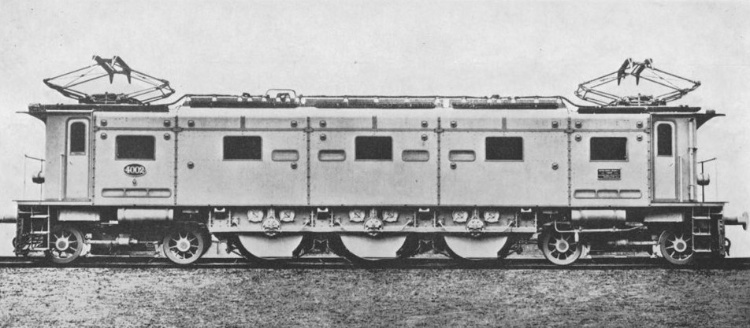

First supplied in 1925 by Swiss Locomotive Works, Winterthur, these were rod-driven C+C articulated locomotives used by the GIPR on the Bombay-Poona section for heavy freights. Later batches were made by Vulcan Foundry, with eletricals from Metropolitan Vickers. 41 were made in total. Originally classed EF/1. They had four 650 hp motors (total power often quoted as 2610hp), driving two three-axle bogies through connecting rods. They also featured regenerative braking (Newport-Shildon, UK). They were known for their superior tractive characteristics on the ghat sections; however, the exposed link mechanisms had to be oiled very frequently in all kinds of weather.

Locally they were known as "khekda" ("crab") They made a curious moaning sound when at rest, and while on the run an unusual swishing sound from the link motion could be heard. They were later used as bankers on the Karjat-Lonavla section, and they were in operation as shunting locos and station pilots until 1992 at Mumbai CST. The first loco of this class #20027 'Leslie Wilson' is preserved at the NRM, New Delhi while #20063 is plinthed at the Kalyan shed.

Dedicated DC freight locomotive introduced in 1971. Made by CLW in batches until 1974, 57 were produced in total. BHEL (HEIL) TM4939AZ traction motors, trimount Co-Co bogies of ALCo design, AC auxiliaries — compressor and alternator from Kirloskar, exhauster by Northey, others by S F India. Air brakes for loco, and regenerative brakes; vacuum train brakes originally, but converted to air later. Better adhesion available through the provision of a vernier control on the starting resistance. Three series-parallel motor combinations weak field operation. These locos could be MU'd up to 3 units.

They had a very loud noise caused by the blowers used to cool the dynamic brake resistors. They initially hauled freight trains in the Bombay - Igatpuri/Pune sections, but also did the banking in the ghat sections after some improvements to reliability. There was a period around 1992 -1996 when the Mumbai division were desperately short of motive power due to the aging and failure prone WCM-1/2/4/5 fleet. The punctuality of trains in and out of CSTM went haywire due to loco failure. During this period the WCG-2 was used on many Mail/Express runs.

In May 2010, the Bhor Ghat section was converted to AC traction, marking the end of their banking duties. The last WCG-2s assigned to shunting duties around Mumbai CSMT were withdrawn in August 2012. All have been scraped, save one. #20158 is preserved at the Kalyan shed.

| Builders | CLW |

| Traction Motors | BHEL (HEIL) TM4939AZ (690hp, 700V, 800A, 1070 rpm, weight 3670kg); axle-hung, nose-suspended, force-ventilated |

| Gear Ratio | 18:74 |

| Pantographs | Two Faiveley AM18B |

| Horsepower | 4200hp (1640hp 1-hour continuous rating in series mode) |

| Axle Load | 22.5t |

| Bogies | Co-Co trimount design |

| Weight | 132t |

| Starting TE | 35.6 tons at 27% adhesion |

| Max. Speed | 80km/h (originally), 90km/h with upgrades |

| Length Over Buffers | 19974mm |

Made by Hawthorne Leslie/English Electric and introduced in 1930, these operated in the Chennai area when it was under 1.5kV DC. 650hp locos. They had a provision for coupling to 'ET' class 4-wheeled battery tenders to allow operating on unelectrified sidings, loop lines, etc. These locos had a roughly rectangular, box-like body with a cab at either end, with a short platform extending from each cab. The cabs each had a door opening on to the platform, and a window (on the right) at the ends. The two bogies had interconnecting linkages to allow easier negotiation of sharp curves. Two 'diamond' style pantographs for current collection. They were eventually withdrawn when the lines they operated in were converted to 25kv AC. There were only four of these locos; one is now preserved at the NRM (#21900).

Dual Current Locomotives

Introduced in 1975, these were IR's first dual current locomotives. Made by CLW to RDSO specifcations, they produced 2900hp in DC mode and 3600hp in AC mode. Bogie design as for WDM-2, WCG-2, and WAM-4 (Alco asymmetric trimount (Co-Co) bogie with cast frames). Speed control via resistance notching in DC mode and tap changer in AC mode. Originally compressed air brakes for loco and vaccum brakes for train, but later retrofitted to dual and air-brake only. Two pantographs, one each for the different modes, though in an emergency they could be interchanged. Motor-alternator from Kirloskar (AEI UK motor), Gresham & Craven exhauster, Kirloskar compressor; other auxiliaries from S F India.

The WCAM-1 did not use a variable ratio auto-transformer in AC mode like the others; it used a fixed-ratio transformer and rectifier bank to convert the OHE supply to 1500VDC. The design of the transformers and notches made this a hard machine to operate, with the fusible links tending to blow often. Of the 28 notches, notches 4, 14, 21, and 28 could be used for continuous operation, although notch 4 was intended for low-speed shunting and was very ineffective. Notches 14, 21, and 28 were the terminal notches of the series, series-parallel, and parallel circuit notch sequences. However they were very robust machines and relatively easy in the handling characteristics.

In 2004, some locos were modified to run only in AC mode with the progress of 25kV AC traction on WR's main line towards Bombay. These locos had their DC equipment entirely removed. However subsequent modifications merely disconnected and isolated the DC equipment. WR started condemning these locos in 2005. However many remained in service until 2015 when WR had sufficient AC locos for its operations. None have been preserved.

| Builders | CLW |

| Traction Motors | Alstom/CLW TAO 659 A1 (575kW, 750V); axle-hung, nose-suspended, forced air cooling |

| Gear Ratio | 61:16, 58:21 |

| Transformer | BHEL BOT 34600; Primary rating 3646kVA, 22.5kV and 162A; Secondary rating 3460kVA, 1730V (DC) and 2x1000A (DC) |

| Rectifiers | 48 cells (321 UFR200) per bridge; Continuous rating 1000A each cubicle; forced air cooling |

| Pantographs | Faiveley AM-12 (AC) and Faiveley AM-18B (DC) |

| Horsepower | 3600hp (AC), 2900hp (DC) |

| Axle Load | 18.8t |

| Bogies | Co-Co asymmetric trimount (ALCo design) |

| Weight | 112.8t |

| Starting TE | 33 tons at 30% adhesion in AC; 28 tons at 25% adhesion in DC |

| Max. Speed | 100km/h (110km/h after regearing) |

| Length Over Buffers | 20950mm |

Built by BHEL to RDSO specifcations, these were an upgrade to the WCAM-1. They have 4700hp in AC mode; DC output was 2900hp. Fabricated trimount Co-Co bogies with secondary suspension; monocoque underframe; shares the TA069 traction motors with WCAM-1. ACEC make static convertor to drive AC auxiliaries. Initially, all were dual braked, but later become only air. They were initially allocted to CR, but were transferred to WR on account of poor performance in DC mode in the graded sections to Pune and Igatpuri. Beginning 2015, all were converted to only AC working and transferred back to Kalyan shed of CR.

Although these locos have the same traction motors as the WAM-4, WCAM-1 and early WAG-5, the power output from the WCAM-2 locos is higher than any of those because in those models the traction motors are underfed (3460kVA transformer in contrast to the 5400kVA transformer for WCAM-2). Under AC traction, the WCAM-2 locos operate with all six motors in parallel (this has been enforced by modifications to these locos), while in DC mode they also operated in the all-series and series-parallel (2S 3P, i.e., three series-pairs of motors in parallel) configurations.

One variant WCAM-2P was produced with a strengthened underframe, better bolsters etc. that resulted in higher maximum speeds (120km/h). These were used almost exclusively for WR's fast Rajdhani and Shatabdi Expresses.

| Builders | BHEL |

| Traction Motors | Alstom/CLW TAO 659 A1 (575kW, 750V); axle-hung, nose-suspended force ventilated |

| Gear Ratio | 62:15, 58:21 |

| Transformer | BHEL 5400 kVA, 32 taps |

| Rectifiers | Two silicon rectifier units D1800N44 (Siemens), 16 cells per bridge. 1000V / 3600A |

| Pantographs | Stone India; AM12 (AC), AM18B (DC) |

| Horsepower | 4700hp (AC), 2900hp (DC) |

| Axle Load | 18.8t |

| Bogies | Fabricated Co-Co trimount |

| Weight | 112.8t |

| Starting TE | 33.4 tons (AC), 26 tons (DC) |

| Max. Speed | 105km/h, 120km/h (WCAM-2P) |

| Length Over Buffers | 20980mm |

Made by BHEL in 1997, these feature a high-adhesion bogie (shared with WAG-7, WDG-3 etc.) and monocoque underframe. 5000hp in AC mode; output was 4600hp in DC mode. Only air brakes for both loco and trains. Speed control by tap changers in AC mode and resistance notching in DC mode. Motors can be placed in different series-parallel combinations. Auxiliaries from Elgi, S F India, Best, Gresham & Craven, etc. Static converter from ACEC for auxiliary supply. They were originally manufactured under a BOLT (build-own-lease-transfer) contract with BHEL. Beginning 2015, many were converted to only AC working by either isolating the DC equipment or a full refit with ballast in place of DC equipment for weight balance. They are all based at Kalyan shed on CR. 53 were made, IR nos. 21881-21934.

In April 2022, IR decided to reclassify a few units that had their motors permanently coupled in parallel as WAG-7M. It is not known whether this reclassification will extend to the rest of class.

In DC mode, rheostatic braking by self-excitation of traction motors was available until 17km/h. Rated for 105km/h in both DC and AC mode (sometimes AC mode rated speed is quoted at 110km/h). Traction motor configurations as in the WCAM-1/2 and WAM-4 (all 6 in series, 2S 3P, or all parallel -- the latter is the only one used under AC traction, enforced now by modifications to the locos). MU operation possible with 3 units. In 2005, all WCAM-3 locos were retrofitted with roof mounted rheostatic braking grids.

| Builders | BHEL |

| Traction Motors | Hitachi HS15250A; axle-hung, nose-suspended, force-ventilated |

| Gear Ratio | 64:18 |

| Transformer | BHEL 5400 kVA, 32 taps |

| Rectifiers | Two silicon rectifier units D1800N44 (Siemens), 16 cells per bridge. 1000V / 3600A |

| Pantographs | Two Stone India; AM-12 (AC), AM-18 B2 (DC) |

| Horsepower | 5000hp (AC), 4600hp (DC) |

| Axle Load | 20.2t |

| Bogies | Fabricated high-adhesion Co-Co |

| Weight | 121t |

| Starting TE | 40.2 tons in AC, 26.8 tons in DC |

| Max. Speed | 105km/h |

| Length Over Buffers | 20980mm |

These are essentially the same as WCAM-3 (similar traction motors, transformers, bogie etc.), but with added weight and changed gearing for freight operations. Can be MU'd up to 4 units. They were introduced in 1999 by BHEL. A total of 12 were made. Like its modern dual current locomotive cousins, many WCAG-1 were also convereted to only AC working when then Mumbai area was converted to 25kV AC. Prior to that, they were often seeing working freights towards the JNPT port and sometimes the Mumbai Port Trust lines.

For other specifications, please check the WCAM-3 class above.

Dual Mode Locomotives

Dual mode locomotive capable of operating under diesel and 25kV AC traction. Only one of this class exists, #71000 home at the Kazipet diesel shed on SCR. Made in 2019 after planning began in 2015, this is IR's attempt to allow for seamless movement between electrified and non-electrified sections after it was noted that traction change detentions at junctions were affecting punctuality. The WDAP-5 is based on the EMD WDP-4D platform, with the same 710G3B engine and EMD/Siemens traction motors. 5000hp under AC traction and 4500hp under diesel. Loco weight of 126t and max axle load of 21t.

The WDP-4D's auxiliary generator and blower was removed to make way for a common traction control system. The loco also features a compact underslung transformer. In order to keep weight of the loco under control and to limit the max. axle load many changes have been made: fuel tank capacity halved to 3000l, body panels made of stainless steel and FRP, lighter weight cattleguard, reservoirs, more compact equipment rack etc. In proving trials in early 2021, the loco ran at 150km/h in the Kota-Shamgarh section of WCR under AC traction. With rapid electrification and a changed rolling stock policy since the project was concieved, it is unclear if more of this class will be made.

Since 2018, various electric sheds have been experimenting with fitting battery packs to old WAM-4 and WAG-5 to enable shunting operations at workshops and yards where electric traction may not be available or to replace aging diesel shunters. While there was no common classification for such converted locos, the class WCAS-4/5 seems to have emerged since 2019. It is believed that Arakkonam, Bhusaval, Kachrapara, Itarsi, Ludhiana and a few others home such locos. Details about the conversion, battery packs used etc. are not known at the moment.

Battery Locomotives

Three of these were built by BHEL in 1987 for use on the NG lines around Gwalior. There are conflicting reports about whether they actually worked trains having had repeated failures during trials. Technical details about batteries are not known. They are believed to have been scrapped in the early 1990s.

The BBCI Railway imported two battery shunters in 1927 from William Beardmore & Co. They were 50-ton, Bo-Bo locos with 240hp rating. Not much else is known about them.