Train Management System

This article is based on explanations by Prakash Tendulkar and his friends at the Mumbai suburban system. A more detailed explanation of TMS is available on Prakash's web site.

Introduction

Train Management System (TMS) is a system implemented by Western Railway, and being implemented now by Central Railway, for integrated management and monitoring of suburban train movements and signalling, as well as planning train routes, diversions, and introduction or withdrawal of rakes in service. CR's TMS covers the major section from CST Mumbai to Kalyan, with four additional minor sections: Ambivli (Igatpuri side), Ambarnath (towards Pune beyond Kalyan), Bhiwandi Road on Vasai side beyond Dombivli, and Dativli Chord Cabin beyond Diva on Panvel side. Implementation is still in progress and is expected to be completed by 2008 or so.

Overview of TMS Components

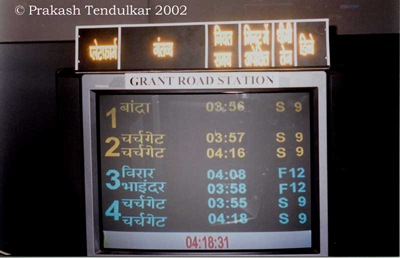

The description here is mainly based on the ongoing implementation of CR's TMS. WR's existing TMS is very similar, although somewhat older. The TMS system covers all train movements in the Mumbai suburban sections of CR, including slow and fast EMUs, as well as the Mail/Express corridors. Signalling and route interlocking information (from signals, points, track circuits, route settings, etc., at various stations) is collected and fed into the TMS system. Train identification information is also collected from each of the train origination stations. The TMS system processes all this information and provides an integrated real-time display and status indications of train positions and movements as well as signals and route interlocking status. TMS management functions use this integrated data to decide on induction and withdrawal of rakes, diversion of trains, planning reversal of rakes, and so on. Control information from TMS is fed to route relay interlocking at several locations to allow remote activation of points and signals and set routes for trains. Within the CSTM station and yard facilities, there are also facilities for automatically setting routes. Information from the TMS is also fed to the PA systems at various stations for real-time updates on train status. In addition, reporting functionality to generate punctuality reports, rake and crew links, train graphs, and unusual occurrence reports is included.

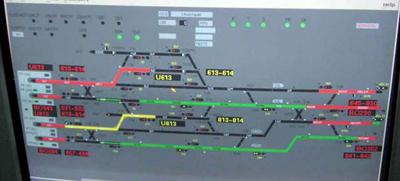

The overall TMS display panel, known as the 'Mimic Indication Panel', is designed to present detailed status of the system at a glance. Station layouts are shown for all stations of interest, including all running lines and optionally the shunting lines of the station. The display is capable of showing the 6 lines from CSTM to Sandhurst Road, 4 lines from Sandhurst Road to Kurla, and 6 lines from Kurla to Kalyan. The two harbour lines from CSTM to Kurla which are at the planning stage, will also be included in the system. EMU rakes can enter or depart the CR system at CSTM, CLA, KLV, or SNPD car sheds. Electric locos can enter or leave the system from loco sheds at CSTM and KYN, while diesels can enter or leave from CLA and KYN. Crew links are managed from CSTM, CLA, TNA, KYN, and KPT. Long-distance trains can enter or leave the system at MZN and BY yards where rake maintenance is carried out. In addition, stabling sidings at CSTM, CLA, TNA, and KYN (and planned ones at BY and THK) are integrated into the system. WR and KR trains can enter or leave the system at Diva. Loco and EMU workshops at PR and MTN are also included in the system. Freight trains can enter or leave the system at Wadi Bunder, Sion, Trombay/Kurla, and New Mulund. The system can cater to the 110 EMU rakes currently in service and more. Expansion capacity is sufficient to handle 55 stations, 150 simultaneous trains, 40,000 indications (and with a rate of 1,000 indications per minute), 8,000 remote commands for signal or points and route operations (and with a rate of 50 route commands per minute and 200 other commands per minute), and 3,000 data inputs for individual train schedules.

Data communications are carried out over fibre-optic networks available between all the stations from CSTM to Kalyan. TMS display panels are usually available with the Asst. Station Masters and other station officials at various stations, and at the section controllers' traction controllers' offices. TMS data input systems are installed in each EMU driving cab as well.

Train Identification

This information is based on WR practice today; CR's TMS will use a very similar system for identifying each rake and its trips. Each rake has a unique rake unit number assigned to it. This is entered at the TMS input unit of the driving cab of the rake, and is broadcast from an antenna mounted on the driving cab. This allows the position of every rake to be known to the TMS system. Every EMU is also assigned a unique train number when it is in service. This number (usually one or two alphanumeric characters, e.g., 'AR') is assigned (and entered manually into the TMS system) when the rake leaves the carshed, and also noted at the end of the day when the rake is stabled. Each EMU also gets a 1 to 4 digit trip number (e.g., '173') for each trip it makes while it is in service during the day. The trip number directly corresponds to each run of the EMU in the timetable. As the train passes various signals and other locations with TMS transponders, the rake unit number is picked up from the transmitting antenna on the driving cab; this is correlated with the train number and then the trip number by the TMS computers and the appropriate status updates are made for the train's position and movement at the TMS units used by station staff or section / traction controllers, and also for updating the PA systems at various passenger stations.