View from the short hood door. In front is the windscreen that the driver looks out from when driving long hood leading. This is a Southern Railways loco from Erode (ED). The padded seat is a rare sight, normally it is a bare wooden stool.

The big white gauge on top of the control stand is the brake pipe vacuum gauge. It is reading 'zero' now as the loco is dead and there is no pressure in the system.

The white gauge in the control stand is the loadmeter, which is an ammeter reading the motor current. There is a green zone (safe operation zone), a timed zone after that (where the loco can work for a short time) followed by the red zone indicating a serious overload. The 'loadmeter' shows current by deflection on the same side (left to right) when motoring (when the loco is pulling) as well as when braking (when dynamic braking).

The black meter above the 'loadmeter' is the accurate electric speedometer driven by the axle-mounted tachogenerator.

The tachogenerator also feeds the recording speedometer below the windshield, which keeps a time-vs-speed track of the loco and is ticking even now (by its clockwork mechanism) even if this loco is dead and very silent.

The black panel on the left of the control stand is the LED lamp indicators for various conditions like wheel slip, ground fault, crankcase exhauster failure, low lube oil pressure.

The single switch next to the LED panel is the emergency engine shutdown switch, it is currently in the 'run' position.

The rotary switch with the yellow label is the headlight switch.

The partially visible black rotary switch next to the headlight switch is used to dim the headlight.

Note the throttle with the black grip, that is currently locked in the zero position.

The oval slot below the throttle is for the 'reverser' handle. The handle has been removed and kept in a cupboard in the short hood as the loco is presently 'stabled' and 'secured'.

Also removed are the two brake handles of A9 (train brake) and the SA9 (loco brake). Each loco has only one set of removable brake handles and reverser, thereby ensuring that only one control stand can be used at any given time.

Note the cotton waste tucked between the brake valves. Many drivers habitually carry a piece of cotton waste in their palms all the time.

Note the twin horn buttons above the throttle.

The single button inline of the reverser slot is the sander switch to spray sand on slipping wheels.

The three black gauges with twin indicators in the control stand are: Brake Cylinder/Brake pipe pressure, Master air reservoir pressure and Vacuum pressure

Note the wiper blade on the windscreen.

Note the spool valve for operating the wiper set in the short hood door and its air hose to the left of the picture. The control used to activate the wiper is the thumbscrew at the bottom of the mechanism (with a speck of red paint) — more the thumbscrew is opened, faster will the wiper wipe!

The alarm bell above the windscreen sounds in event of engine trouble like overspeeding, hot water alarm or low oil pressure trip.

The red button and the round window (with a pointed needle indicator) is the 'GF' relay, which operates on 'Ground Fault' or 'Power Ground', when the main generator short circuits.

One horn trumpet is partially visible near the top of the windshield.

Note the 'caution order' stuck in between the loose metal sheets of the control stand. There is no other place to keep it for ready reference.

Is the rag stuck near the GF relay meant to prevent the covers of the control cabinet from vibrating?

Enjoy the view!

Another view of the same loco, note the driver's log on the control stand, and the vacuum gauge at 50 cms meaning brakes are fully off.

The throttle is fully open in the eighth notch and the train is travelling at its maximum 'booked' speed.

The other black lever near the throttle is the motoring/braking lever.

Moving the motoring/braking lever away from the driver causes the loco to perform a 'MT' or 'manual transition' whereby the motors are connected from series parallel to full parallel. Further movement of this lever causes the next transition where the the motors connect in the full parallel shunt (weak field) position. Normally the transitions occur automatically and the 'MT' facility is used only to gain advantage during the acceleration.

Only when the throttle is in the zero notch, the motoring/braking lever can be brought forward towards the driver, activating the dynamic brakes. The dynamic brake effort is maximum when the motoring/braking lever is fully forward.

Note the circuit breakers on the side of the control stand for connecting the generator field, fuel pump motor and auxiliaries.

The box on top of both the control stands is the flasher, which switches the yellow flasher light near the headlight. The flasher is meant to attract the oncoming train's attention in event of an emergency or hazard.

Just visible in front of my fellow footplater's thigh is the 'fireman's emergency valve' which directly opens the brake pipe to atmosphere, thereby destroying vacuum and stopping the train in event of the driver being incapacitated.

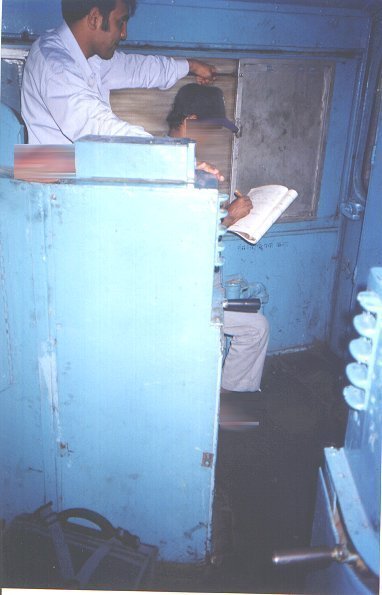

A look at the assistant seat. Filling the log books is a constant activity on the footplate.

Note the second 'fireman's emergency valve', where the hinged cap is clearly seen in front of the assistant's knee.

Note the motoring/braking levers on both control stands.

The glass on the assistant's window has been replaced by a sheet of galvanised tin.

The assistant looks out through the windscreen set in the door in front of him.

View from the assistant's seat, looking back. This would be the driver's seat when the loco is driving short hood leading.

Note the 'Hasler' speedometer, which also records the loco speed on a circular chart. The speed indicated is just under 40 km/hr. The indication on the Hasler is incremented in small steps rather than continuously.

The white notice stenciled on the windscreen is a reminder to wind the Hasler's clockwork mechanism to advance the circular chart. It urges the drivers to 'wind the clock key daily at 0000 hrs at right for the Hasler'.

Note the throttle locked in the zero position and the horn buttons.

The A9 and the SA9 brake valves without their handles.

Note the folding armrest outside the window.